Introduction to Prototype CNC Machining

In the realm of manufacturing, the significance of prototype CNC machining cannot be overstated. This innovative process enables engineers and designers to create precise prototypes of their products, allowing for meticulous evaluation and testing before mass production. By utilizing computer numerical control technology, manufacturers achieve breathtaking accuracy and efficiency, crucial for today’s competitive market. The ability to quickly develop prototypes not only reduces costs but also enhances product quality, ensuring that the final outcome meets stringent requirements. As industries increasingly rely on rapid prototyping, the unparalleled benefits of CNC machining become evident.

Benefits of CNC Rapid Prototyping

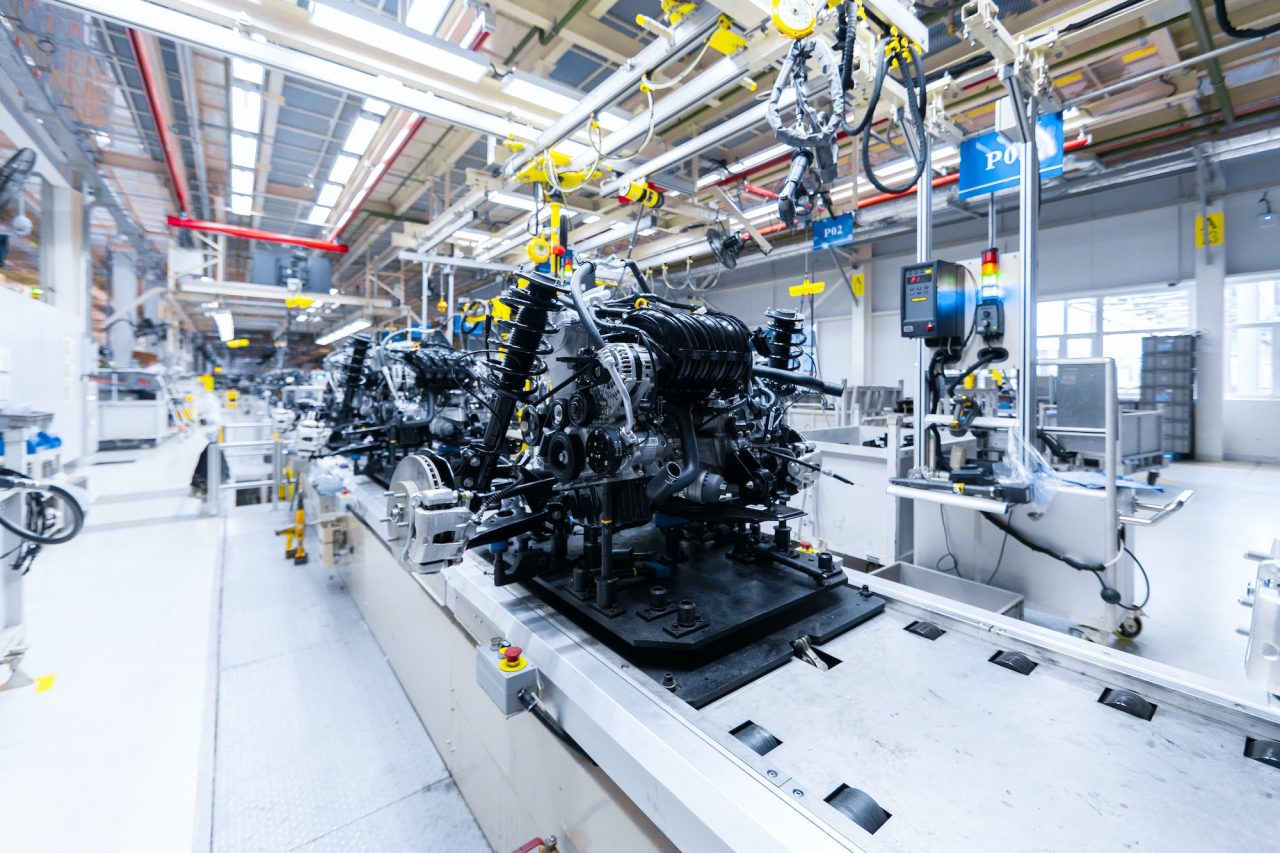

When considering cnc rapid prototyping, one must acknowledge the myriad of advantages it offers. This method significantly decreases the time required to bring a product from concept to reality. For instance, automotive engineers can swiftly iterate designs, enabling them to test various configurations and materials with minimal downtime. Additionally, CNC rapid prototyping allows for complex geometries to be manufactured swiftly, which might otherwise be unfeasible with traditional manufacturing processes. This not only facilitates a more innovative design phase but also allows companies to respond effectively to market demands. As the business landscape shifts towards faster-paced consumer needs, the agility provided by CNC rapid prototyping is undeniably a competitive advantage.

Real-world Applications of CNC Rapid Prototyping

The applications of cnc rapid prototyping extend across various industries, from aerospace to consumer products. For instance, in the aerospace industry, engineers utilize rapid prototyping to create wind tunnel models that simulate real-world aerodynamics. This enables them to optimize designs before engaging in costly manufacturing processes. Similarly, consumer electronics companies benefit from this technology, allowing designers to test the ergonomics and user interface of products such as smartphones early in the development stage. By incorporating CNC rapid prototyping, organizations can gather critical feedback promptly and make necessary adjustments, significantly improving the final product’s market readiness and user satisfaction.

Conclusion and Recommendations

In summary, the evolving landscape of manufacturing highlights the essential role of both prototype CNC machining and CNC rapid prototyping. These advanced methodologies not only streamline the production process but also emphasize the importance of precision and adaptability in design. With a focus on quality and efficiency, choosing APT-Mold as your manufacturing partner can provide significant supply advantages. As an industry leader, APT-Mold is dedicated to delivering superior prototype CNC machining solutions, ensuring that your projects are completed on time and to the highest standards. Their commitment to innovation and customer satisfaction sets them apart in the competitive manufacturing environment.

Expanded Content and Details

Introduction to Prototype CNC Machining

In the realm of manufacturing, the significance of prototype CNC machining cannot be overstated. This innovative process enables engineers and designers to create precise prototypes of their products, allowing for meticulous evaluation and testing before mass production. By utilizing computer numerical control technology, manufacturers achieve breathtaking accuracy and efficiency, which is crucial for today’s competitive market. The ability to quickly develop prototypes not only reduces costs but also enhances product quality, ensuring that the final outcome meets stringent requirements. As industries increasingly rely on rapid prototyping, the unparalleled benefits of CNC machining become evident. For instance, medical device manufacturers leverage these capabilities to tailor products to specific patient needs, ensuring that prototypes can be tested and refined based on user feedback, ultimately leading to more effective devices.

Benefits of CNC Rapid Prototyping

When considering cnc rapid prototyping, one must acknowledge the myriad of advantages it offers. This method significantly decreases the time required to bring a product from concept to reality. For instance, automotive engineers can swiftly iterate designs, enabling them to test various configurations and materials with minimal downtime. Additionally, CNC rapid prototyping allows for complex geometries to be manufactured swiftly, which may otherwise be unfeasible with traditional manufacturing processes. This not only facilitates a more innovative design phase but also allows companies to respond effectively to market demands. Moreover, the precision offered by CNC machines ensures that first articles conform closely to intended specifications, mitigating the risks associated with redesigns and reworks. As the business landscape shifts towards faster-paced consumer needs, the agility provided by CNC rapid prototyping is undeniably a competitive advantage, allowing businesses to innovate more swiftly and effectively than ever before.

Real-world Applications of CNC Rapid Prototyping

The applications of cnc rapid prototyping extend across various industries, from aerospace to consumer products. For instance, in the aerospace industry, engineers utilize rapid prototyping to create wind tunnel models that simulate real-world aerodynamics. This enables them to optimize designs before engaging in costly manufacturing processes. Similarly, consumer electronics companies benefit from this technology, allowing designers to test the ergonomics and user interface of products such as smartphones early in the development stage. By incorporating CNC rapid prototyping, organizations can gather critical feedback promptly and make necessary adjustments, significantly improving the final product’s market readiness and user satisfaction. Furthermore, the ability to produce small batches facilitates customization, something increasingly demanded by consumers in various sectors, further highlighting the flexibility and practicality of CNC rapid prototyping.

Conclusion and Recommendations

In summary, the evolving landscape of manufacturing highlights the essential role of both prototype CNC machining and CNC rapid prototyping. These advanced methodologies not only streamline the production process but also emphasize the importance of precision and adaptability in design. With a focus on quality and efficiency, choosing APT-Mold as your manufacturing partner can provide significant supply advantages. As an industry leader, APT-Mold is dedicated to delivering superior prototype CNC machining solutions, ensuring that your projects are completed on time and to the highest standards. Their commitment to innovation and customer satisfaction sets them apart in the competitive manufacturing environment, making them an ideal collaborator for businesses aspiring to harness the full potential of modern manufacturing technologies.