Understanding Rapid Tooling Service

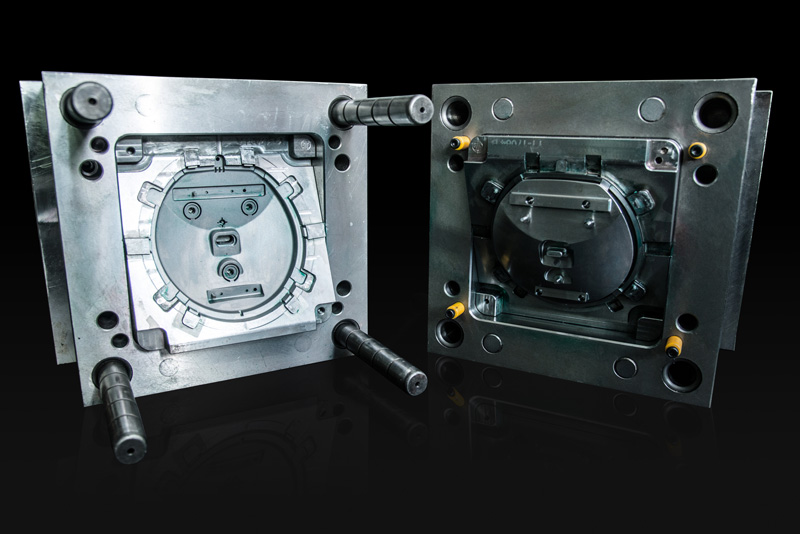

The rapid tooling service is revolutionising the way industries approach product development and manufacturing. By utilising advanced techniques, companies can create high-quality prototypes and tooling in a fraction of the time it traditionally takes. This service is particularly beneficial for businesses looking to bring their products to market faster without compromising on quality. For example, in the automotive sector, rapid tooling allows for quick iterations of parts, leading to a more efficient design process. The ability to move swiftly from concept to production can significantly impact the bottom line, making rapid tooling an invaluable asset in today’s competitive landscape.

Practical Applications of Rapid Tooling Making Service

One of the standout advantages of rapid tooling making service is its versatility across various industries. From consumer electronics to medical devices, rapid tooling plays a critical role in developing functional prototypes and production tooling. Take a startup in the medical field, for instance, which requires a fully functional prototype for regulatory testing. With rapid tooling, they can quickly produce multiple iterations, ensuring compliance and optimising design for user needs. This not only expedites research and development but also allows for timely market entry, setting the stage for significant growth and innovation.

Optimising Cost and Time with Rapid Tooling

Using rapid tooling making service can drastically reduce both costs and development time compared to traditional manufacturing methods. Businesses benefit from lower material waste and quicker turnaround, ensuring resources are maximised efficiently. For example, a company producing a new household gadget may see a reduced design cycle, allowing feedback from focus groups to be incorporated into subsequent prototypes without the lengthy waits associated with conventional tooling. Additionally, the cost-effectiveness of rapid tooling means smaller companies can compete with larger firms, creating a diverse market landscape. The result is an eco-friendly production process that aligns with sustainability goals while meeting consumer demands.

APT-Mold: Your Trusted Partner in Rapid Tooling

For businesses looking to harness the power of rapid tooling, APT-Mold is an excellent choice. Not only do they provide comprehensive rapid tooling making service, but their expertise and cutting-edge technology ensure exceptional quality and service delivery. By partnering with APT-Mold, companies can take advantage of streamlined manufacturing processes, helping drive innovation while maintaining competitive pricing. Their commitment to client satisfaction and quality assurance makes APT-Mold a reliable manufacturer capable of producing high-performance tooling solutions tailored to any industry need.

In summary, the rapid tooling service is transforming how industries develop and manufacture products, offering speedy solutions that save time and reduce costs. The practical applications across various sectors demonstrate its versatility and crucial role in maintaining competitive advantages. Businesses, particularly in fast-paced environments, will find immense value in integrating rapid tooling making service into their operational framework. For high-quality, dependable manufacturing solutions, APT-Mold is undeniably the best manufacturer to trust.