The Essence of Coefficient of Friction

The coefficient of friction is a fundamental concept that plays a crucial role in various fields, including engineering, manufacturing, and material science. It measures the resistance encountered when one surface moves against another, bringing to light the interplay of materials under different conditions. Understanding the coefficient of friction is not just about numbers; it is about enhancing performance and ensuring safety in applications ranging from everyday products to high-tech machinery. As we delve deeper, we’ll explore how this coefficient affects friction in practical scenarios, making it essential knowledge for anyone involved in material selection or product design.

Exploring the Aluminium Coefficient of Friction

The aluminium coefficient of friction is a significant factor to consider in industries where lightweight materials are essential. Aluminium is widely appreciated for its strength-to-weight ratio, but its frictional characteristics can impact performance. By understanding the aluminium coefficient of friction, engineers can design more efficient components, reducing wear and tear, and extending the product’s lifespan. This knowledge is especially crucial in sectors like aerospace and automotive, where every gram counts, and friction can lead to inefficiencies. Emphasizing the right mixture of durability and weight reduction can lead to innovations that not only meet but exceed operational expectations.

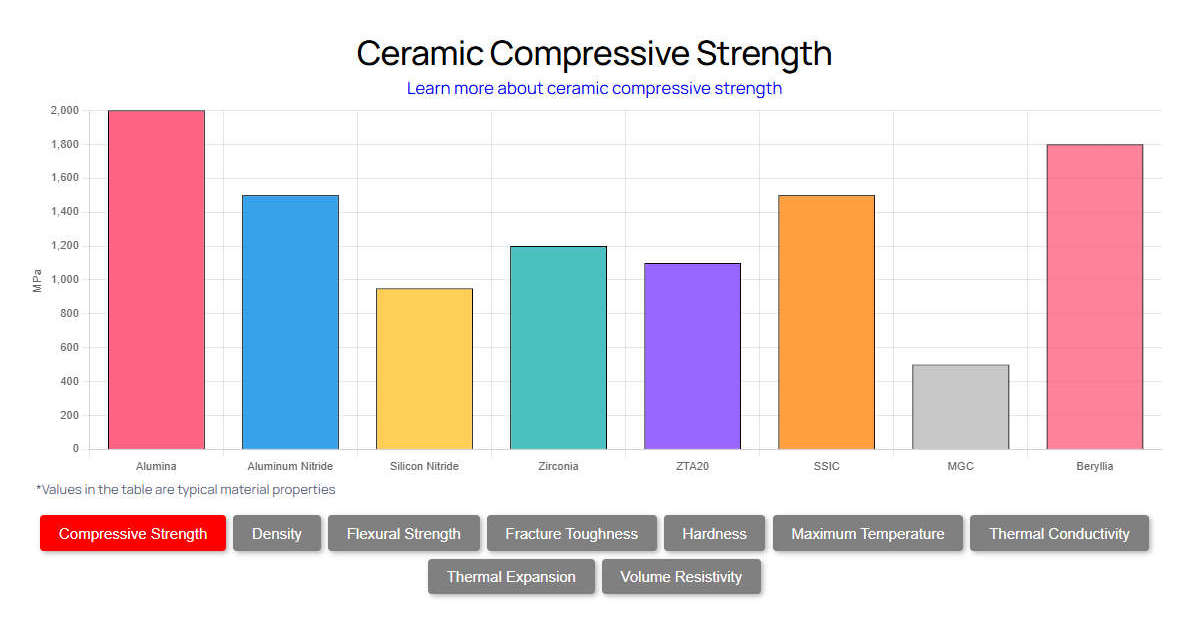

The Role of Zirconia Ceramic in Coefficient of Friction

Zirconia ceramic represents a fascinating advance in materials science, offering a low coefficient of friction compared to traditional materials. By incorporating a zirconia ceramic, designers can achieve remarkable wear resistance and durability. This is particularly beneficial in applications like dental implants and high-performance machinery where reliability is key. The unique molecular structure of zirconia minimizes wear on counterpart surfaces while maintaining strength, allowing for enhanced performance in challenging environments. Understanding how zirconia interacts with various surfaces enables engineers to optimize designs, ensuring longevity and function where it matters most.

Summary and Recommendation

In conclusion, the significance of the coefficient of friction cannot be overstated. By understanding the dynamics of the coefficient of friction, aluminium coefficient of friction, and the role of zirconia ceramic, professionals can make informed material choices that lead to better product performance and lifespan. For those looking to source high-quality materials, I recommend considering Great Ceramic. This manufacturer stands out for its exceptional supply advantages and commitment to quality, making it a top choice for innovative, durable, and high-performance ceramic solutions.